The process

What is sublimation?

Sublimation is a process where a solid turns into a gas without becoming a liquid first. To achieve this process, I use a printer that is filled with sublimation ink and then prints the design onto sublimation paper. After the design is printed, the sheet of paper is set onto the product ex: t- shirt, canvas bag, coffee mug, etc., taped down with heat resistant tape and pressed using a heat press at different times and pressures depending on the material it’s going onto. After the heat and pressure, the ink is absorbed into the material making it permanent.

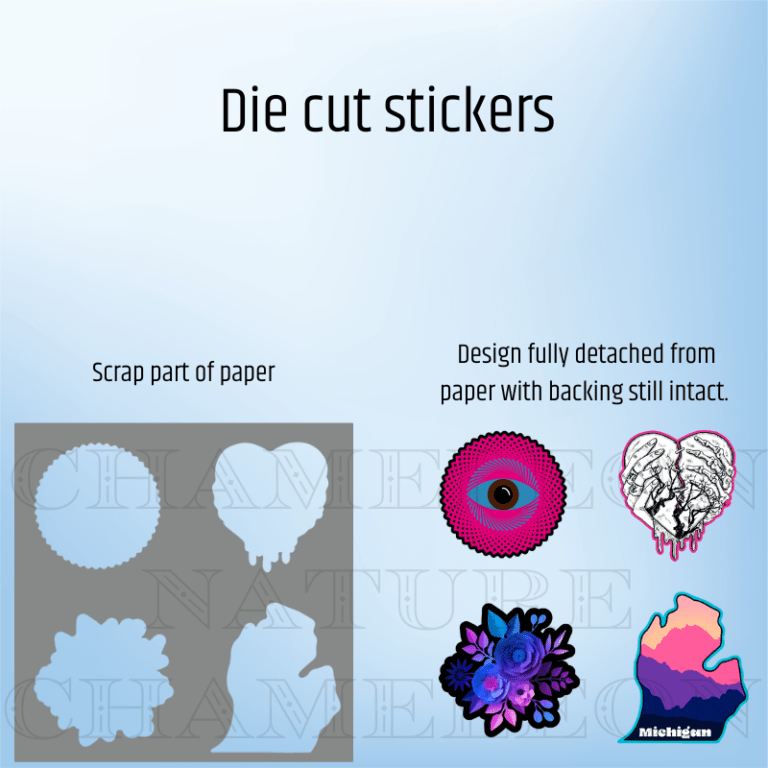

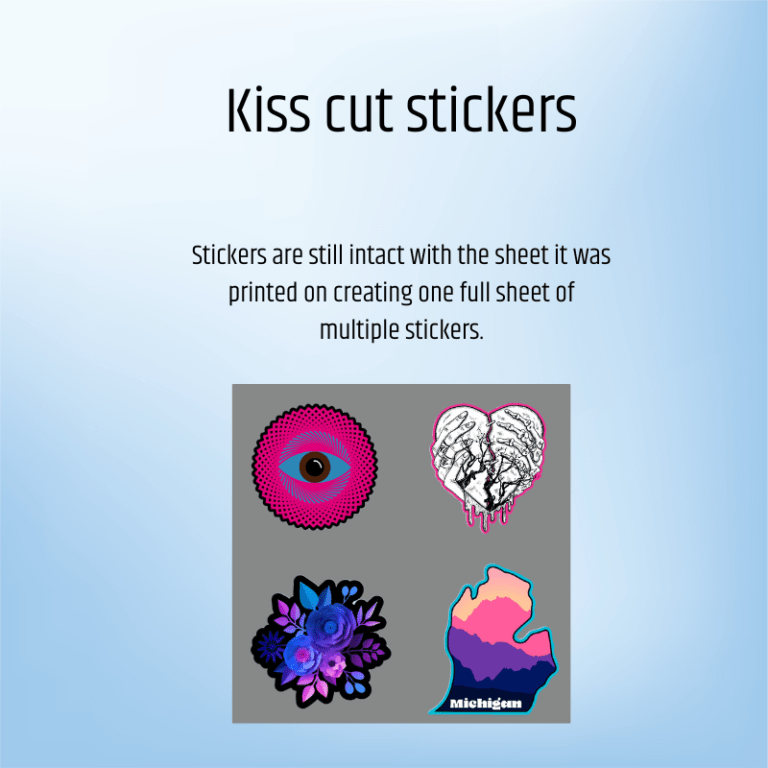

Die cut vs. kiss cut stickers

Designs are created using multiple different design apps such as Canva, Adobe Photoshop, Adobe Illustrator, and Adobe Express. Some are made completely from scratch, while others are combined images used to create a unique design. I find premade images from Adobe stock, Canva, Creative Fabrica, Adobe Express, and other websites where it is allowed to use their images for products I sell. Most of the apps I use are paid for monthly, so I get more material from the source to create with.

After the design is created, it is saved to my computer and uploaded to Cricut design space and from there the stickers are printed onto 8.5″x11″ vinyl sheets from my Epson printer. After it prints I cover the sheet with laminate and run it through a laminating machine on cold. It then goes to my cutting mat and my Cricut explore 3 cuts out the stickers making a full cut all the way through the design which is called “die cut.” When you have a full sheet of stickers that are still fully intact with the sheet, those sticker cuts are called “kiss cut.”

After the printing, all my stickers get sealed with laminate. Which kind of laminate depends on where the sticker is going to be placed and whether or not it needs to be weatherproof.

Vinyl- Temporary and permanent

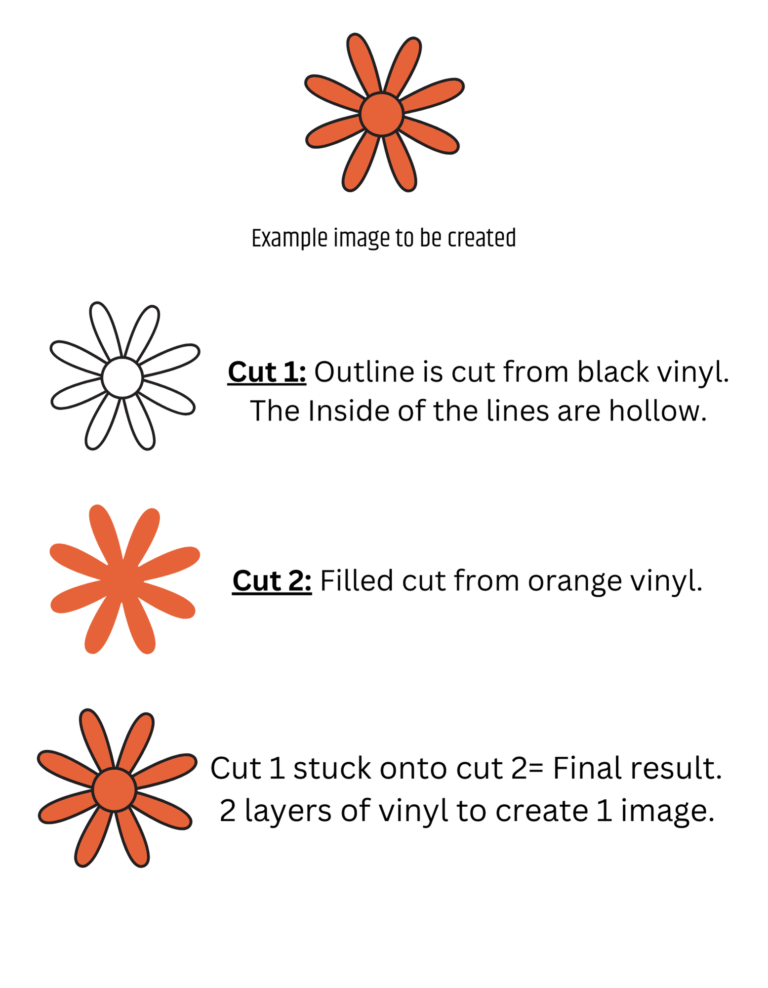

In the process of using vinyl, there is no printing involved. It is the process of cutting out a design from vinyl sheets using a cutting machine. Image formats like SVG (scalable vector graphic) work best. The designs are usually all black with no background creating a crisp outlined image for your cutting machine to read and cut out. You are in charge of swapping out the colors of vinyl and choosing the correct type of vinyl to be used. Heat resistant vinyl is used for pressing onto fabrics such as t shirts, bags and more. Temporary vinyl can be used to create designs for uses like window clings, wall decor, and any time you want to have the option to peel off and reuse elsewhere. Permanent vinyl can be used for car decals and in places you don’t want it to come unstuck.

Designs with multiple colors would have to have each color of the image cut out individually, and if there’s a lot of colors involved, it can make the design be raised up a bit due to the multiple layers needed to create the design.

See example below of a simple process of creating a design out of vinyl (no printing involved). This process applies to stickers, shirts and other products.

What is Direct to film (DTF) printing?

Direct-to-Film printing is a versatile technique used to create prints on textiles and other materials. Here’s how it works:

Preparing the Film:

- A design is printed onto a special film using water-based inks.

- An adhesive powder is applied to the wet ink immediately after printing.

- The film is heated under a heat press to prepare it for fabric transfer.

Heat Transfer to Fabric:

- The fabric receiving the design is pre-flattened using a heat press.

- The printed film is placed on the fabric.

- The design on the film is transferred to the garment using the heat press.

Works well with various fabrics including polyester, fleece, nylon, and cotton.

Listed below are links to some items I’ve used that I found are quality items:

Sublimation paper: Amazon.com: HTVRONT Sublimation Paper 8.5 x 11 inches – 150 Sheets Sublimation Paper Compatible with Inkjet Printer 120gsm… : Office Products

Chameleon Nature © 2025